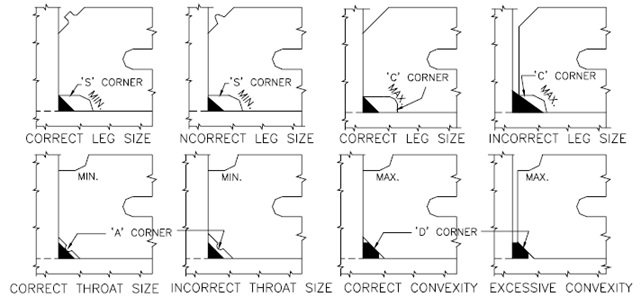

The finished welds shall be visually inspected and shall conform to the size and contour

specified in the drawings (Acceptable and defective weld profiles are illustrated in

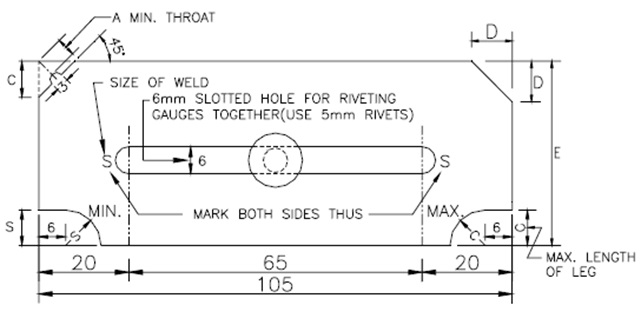

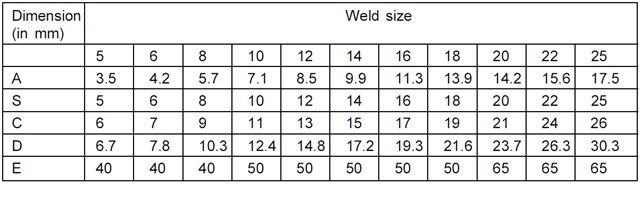

Fig. 24 to 28). Conformity of fillet welds as to size and contour shall be determined by

the use of gauges (See Appendix ‘B’) Concavity and excessive convexity of fillet welds

shall be marked for correction.

Welding gauges are essential tools in the welding industry for measuring, inspecting, and evaluating

welds. Made of metal or plastic and available in various shapes and sizes, they ensure welds meet

required standards for strength and durability. These gauges help maintain weld quality by providing

feedback on weld profiles, joint fit-up, dimensions, and welding parameters, allowing for the

identification and correction of defects.

Fillet Weld Gauges are tools used to measure the size of fillet welds, which are commonly found in

lap joints, T-joints, and corner joints. These gauges usually feature a set of blades or notches in

various sizes and are used for measuring various weld parameters.